FarmITda

Smart Farm Management Solution

Aquaculture management

for early detection of

tank changes and proactive response

Sensors, equipment, and video are integrated for automated monitoring and control.

Water quality data (temperature,

dissolved oxygen, pH, ammonia) and devices like feeders, pumps

and valves can all be managed from a single interface on

the smart aquaculture platform.

-

Realtime Control & Monitoring

Real-time monitoring and alerts for temperature, oxygen, salinity and turbidity

Conditional automation of feeders, pumps and valves

-

On-site Video & Remote Control

Real-time aquaculture farm streaming with timeline and snapshots.

Remote monitoring and control via dedicated mobile app.

-

Data-Driven Decisions

Feeder, water quality, and environmental analysis reports.

Thresholds and guidance tailored by species and season.

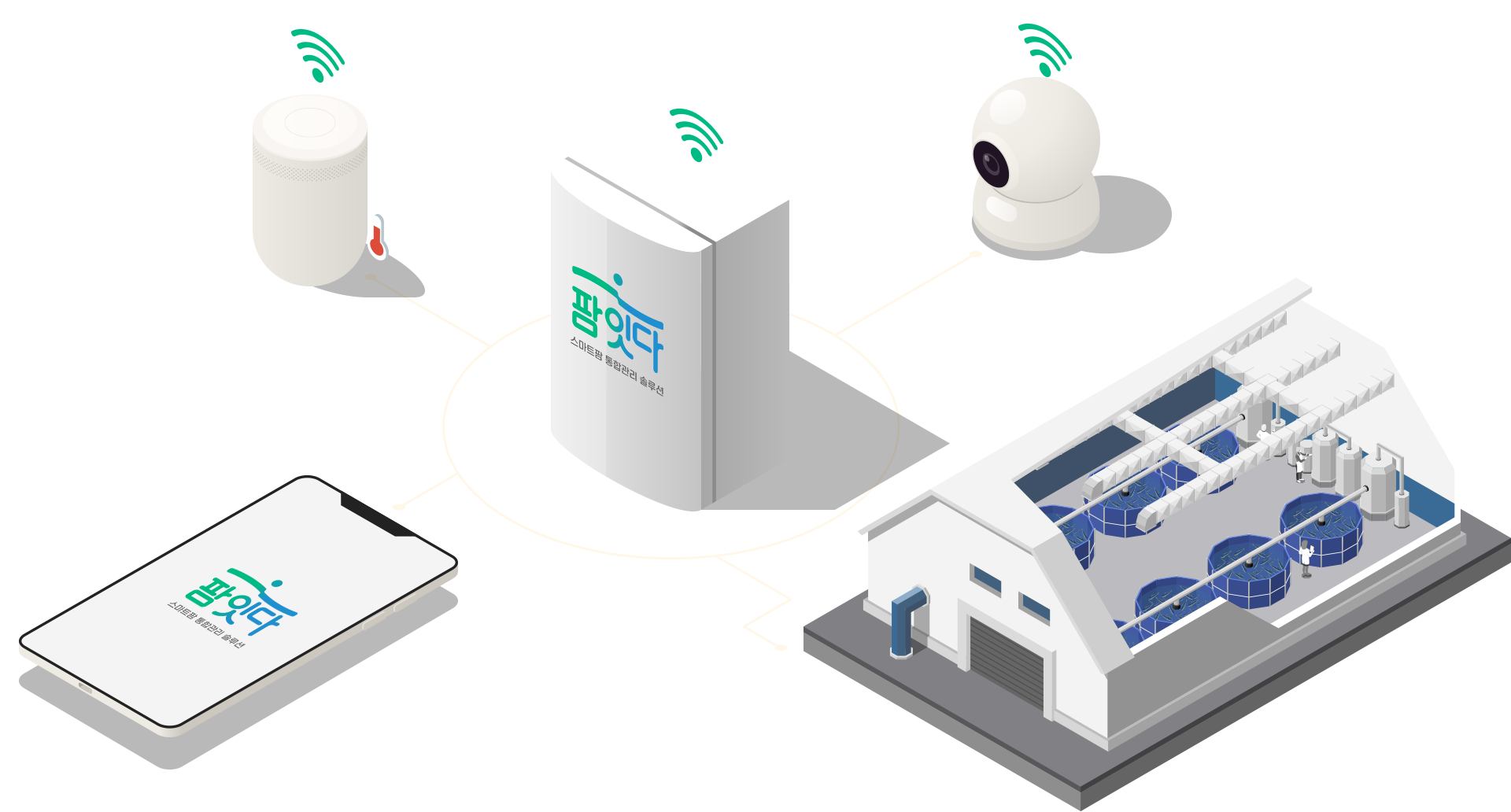

Architecture

XOS architecture integrates sensors, equipment, video, and data into a seamless flow, connecting on-site gateways, cloud and web/mobile platforms via standard APIs.

- Modular Design — Flexible expansion with sensor, equipment, video and report modules

- Offline-First — Continue data entry even when saving is unavailable with automatic synchronization once connected

- Web Standards & Responsive Design — Consistent experience across various OS, browsers and devices

- Security & Compliance — Role-based permissions, audit logs and encrypted communications

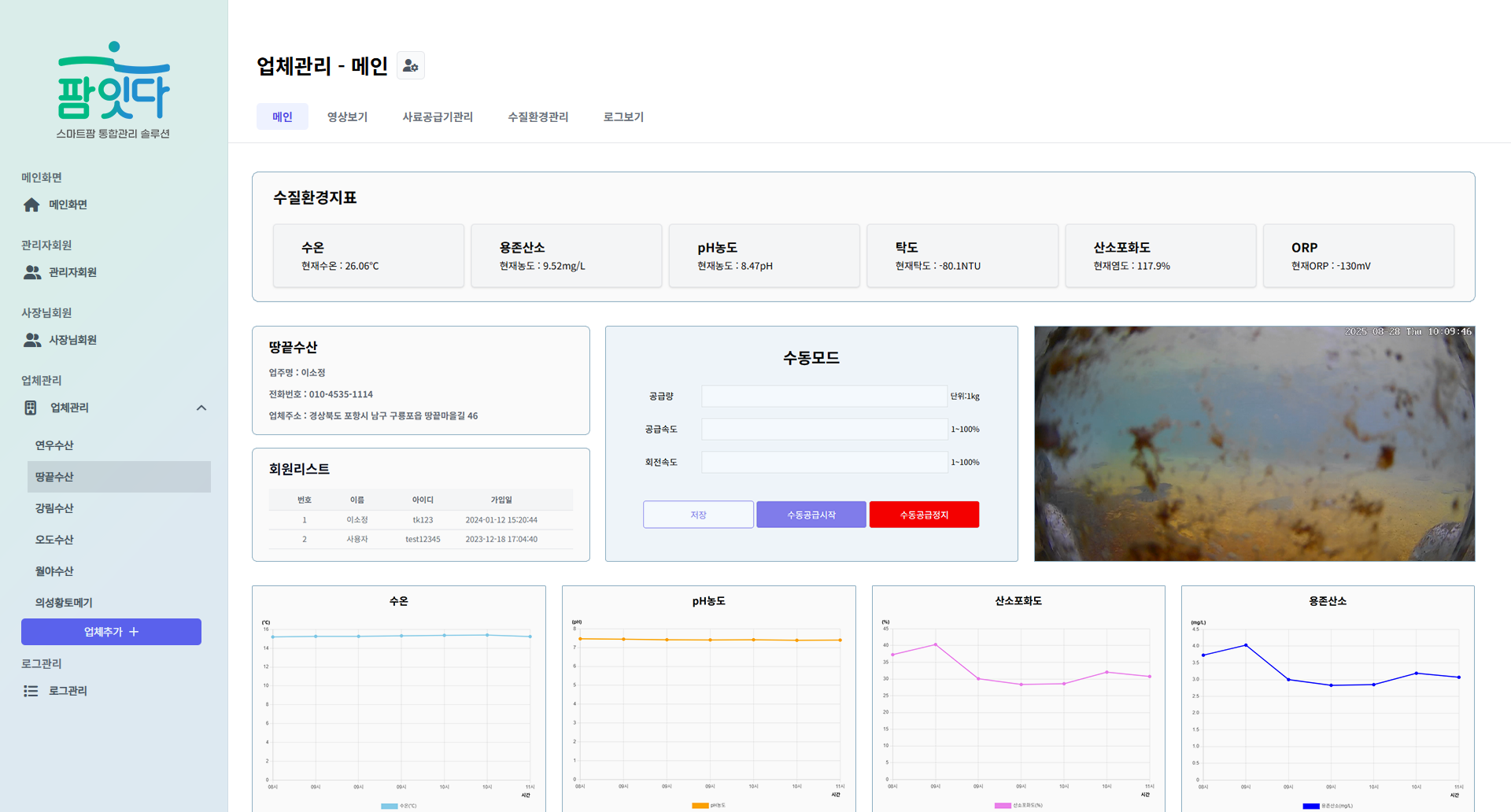

Monitoring & Control

Maintain stable conditions with second-level sensing and conditional automation.

Schedules and rules can be saved by

species and tank for reuse.

- Real-time Environment – Water temperature, dissolved oxygen, salinity, turbidity, weather/tide

- Automation – Conditional control of feeding, aeration, pumps and valves

- Notification – Push notifications for thresholds, equipment anomalies, and maintenance schedules

- Reports – Daily/weekly operational status, feed conversion ratio (FCR) and correlation analysis

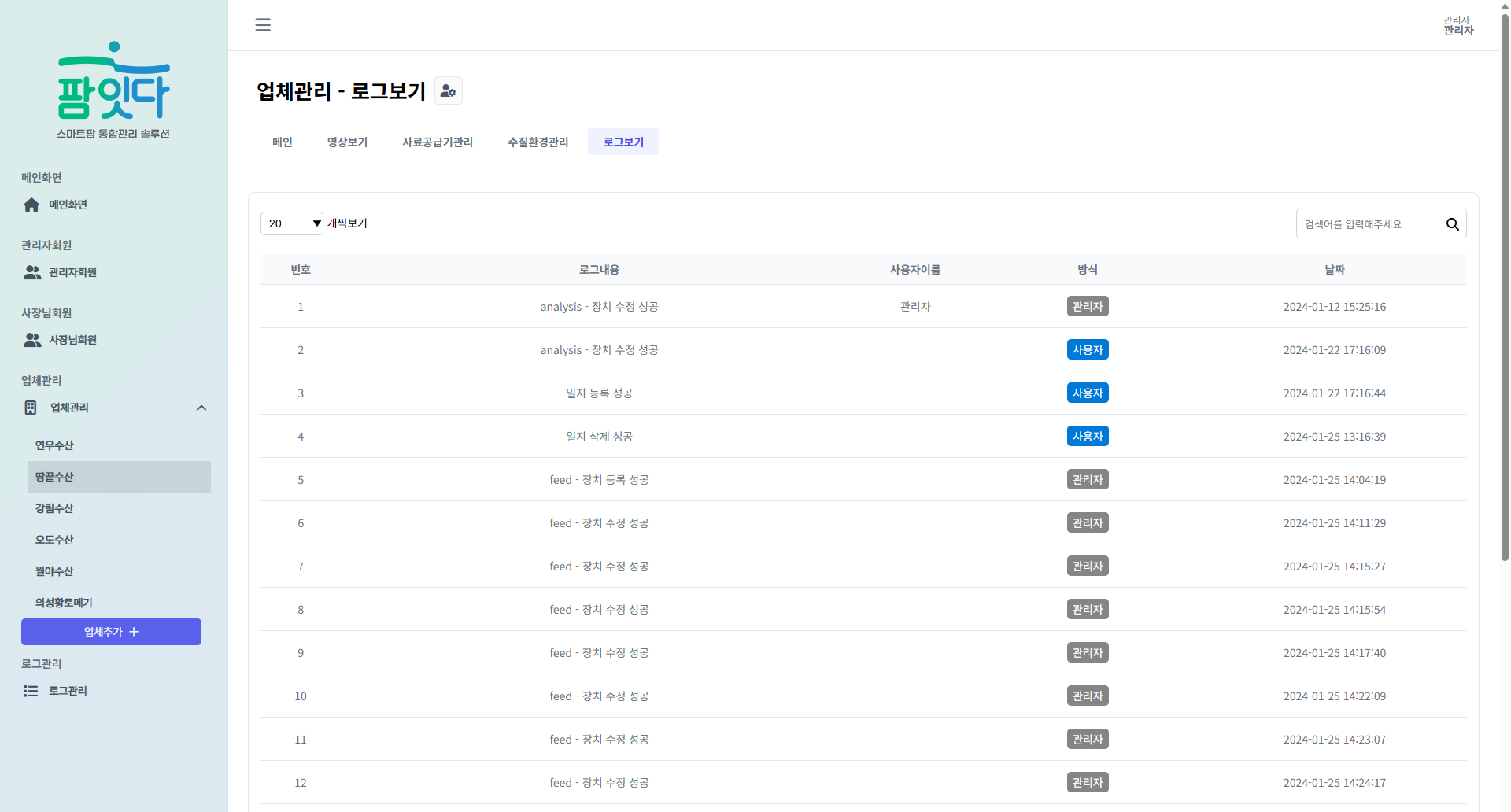

Security & Reliability

Prioritize operational stability and data reliability.

Track changes via role-based permissions and audit logs, and

ensure safe data storage based on connection status.

- Permissions & Audit — Role-based access control and equipment control history tracking

- Continuity — Maintain offline data entry with automatic save/synchronization upon reconnection

- Backup – Regular backups and recovery scenarios

Usage Environment

-

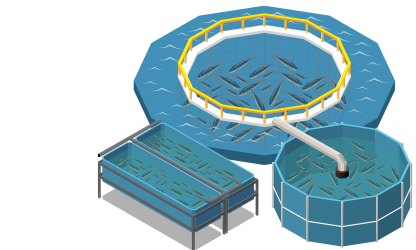

Offshore Cage

Coastal & Inshore Cage Farms

-

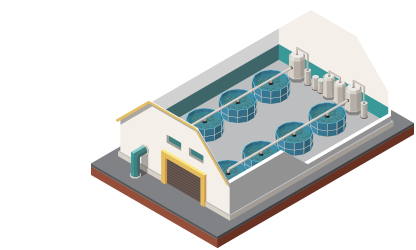

Onshore Tanks

Tank-Based RAS Aquaculture Farm

-

Hatchery / Grow-out

Stage Management: Hatchery, Fry, Grow-out

-

Integrated System

Integration with sensors, equipment, and ERP/logistics systems.

FAQ

QWhich sensors and equipment can be integrated?

QCan it be used even if the network is unstable?

QHow is real-time video provided?

QWhat information is included in the data reports?